Manufacturing analytics: So you’re collecting data, but can you use it in a recall?

It’s when manufacturers are faced with a recall or warranty claim that they realize data collection alone has little value if they can’t easily access and analyze it. Learn how we helped one manufacturer of agricultural machinery use their data to improve their root cause analysis time from weeks to minutes!

Choosing the right camera for your vision inspection

Are your machine vision needs on the production line better served with a smart camera, or a “dumb,” more basic one? Before you make the investment, consider these factors that can dictate which option is better for a given situation.

How to effectively store and manage machine vision images and data

The information generated by machine vision systems puts a whole new spin on the term “big data.” The raw image files output from vision systems are huge, and manufacturers can generate terabytes of image data in a month—even in a week! So, what do you do with all this data? Read more to find out!

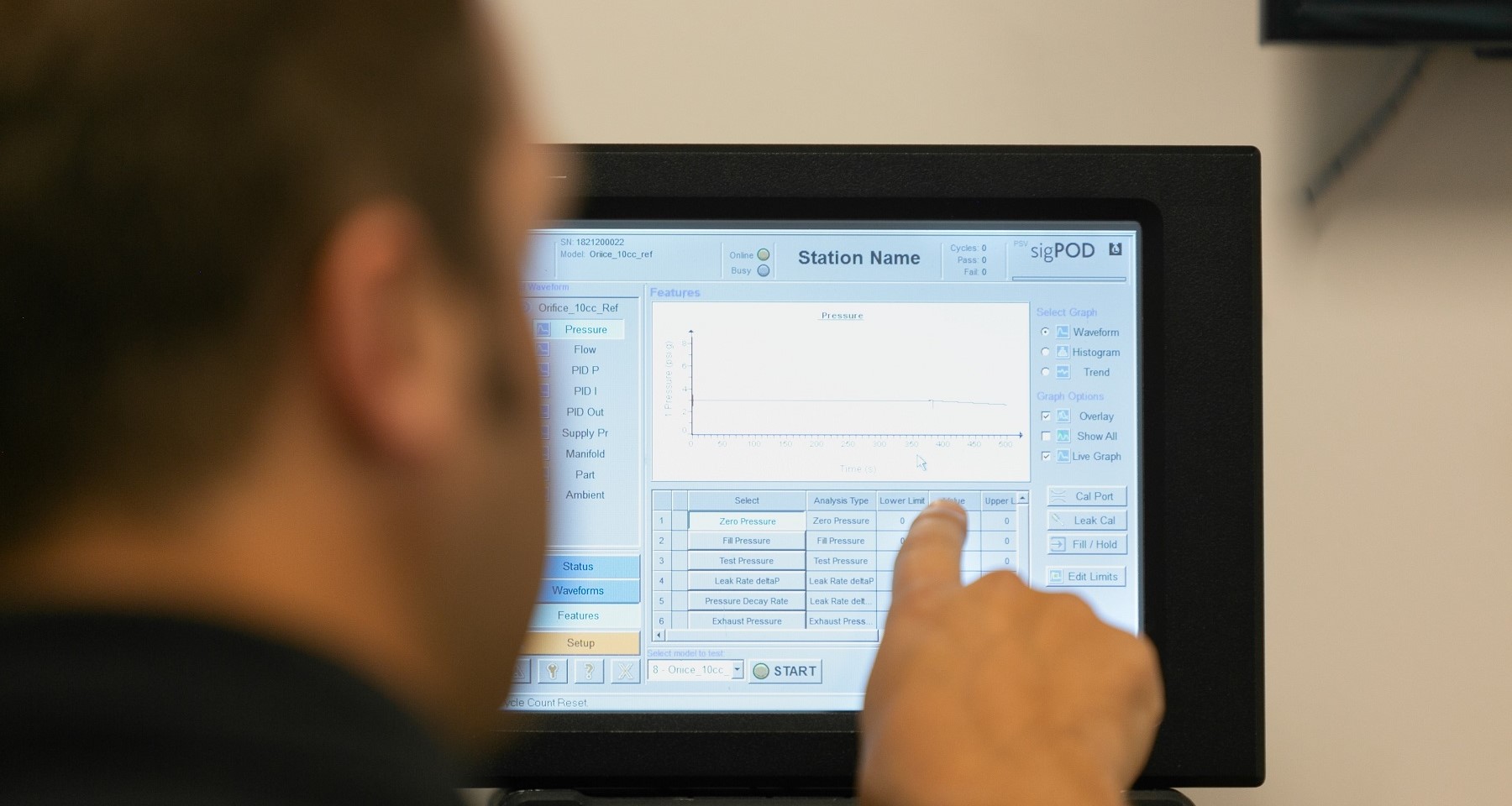

Factors in identifying proper test pressure for your leak test

A chief goal when it comes to optimizing any leak test is to ensure if the cycle time of the test can keep up with the pace of production. One factor in optimizing the test so that it can cycle as many parts as quickly as possible with an acceptable range of repeatability and reliability is test pressure. Consider the following factors when identifying proper test pressure for your leak test.

Digital process signature analysis: The first step to Industry 4.0

Many manufacturers continue to focus on data collection rather than data utilization. They don't yet have the modern data analytics tools in place that will allow them to squeeze from their part data the actionable insight that is crucial to meeting Industry 4.0 benchmarks they are seeking for quality, yield and traceability. Learn why digital process signatures are your first step to meet Industry 4.0 objectives.

A more reliable weld test through data, without the need for destruction

The traditional approach to testing weld integrity is often destructive pull-test, with its shortcomings. Perfectly good assemblies may be ruined, while faulty ones can still slip through and be shipped for use. With digital process signature analysis, however, all the metrics that identify problems can measured to catch defective parts.

Battery pack leak test: The challenges of getting an honest result

A variety of factors make it difficult to simulate the exact leak conditions battery packs will experience in the field, but there are strategies to achieve an effective battery pack leak test. Here are two of the key challenges you are likely to encounter with battery pack leak testing and strategies to overcome them.

How the network edge can help your plant or industrial operation optimize cloud resources

Many manufacturing and industrial facilities have chosen to recruit capacity from a public cloud service provider to help them manage their data. However, while the cloud is a relatively cost effective, simple to manage, and scalable solution to suit your needs, it can also create some other challenges. Learn more.