Contributed by: Sciemetric Staff

It’s only in recent years that manufacturers have begun to embrace the power of manufacturing data collected from processes and test stations on a production line to improve quality, boost efficiency and drive profitability.

With buzzwords like “Manufacturing 4.0,” “Industry 4.0,” and “IIoT” commanding executive discussions across the industry, manufacturers are now feeling the pressure to implement “smart” strategies in their factories.

The problem is that many manufacturers think that simply connecting their devices for manufacturing data collection is enough. It’s when manufacturers are faced with a recall or warranty claim that they realize the data alone has little value if they can’t easily access and analyze it.

A typical manufacturer: Inaccessible manufacturing data

With data stuck in silos, production was halted for weeks during root cause analysis

We worked with one manufacturer of agricultural machinery that struggled with a mashup of databases and data retrieval systems across its global operation. Each plant operated with its own standards, processes and metrics for quality management.

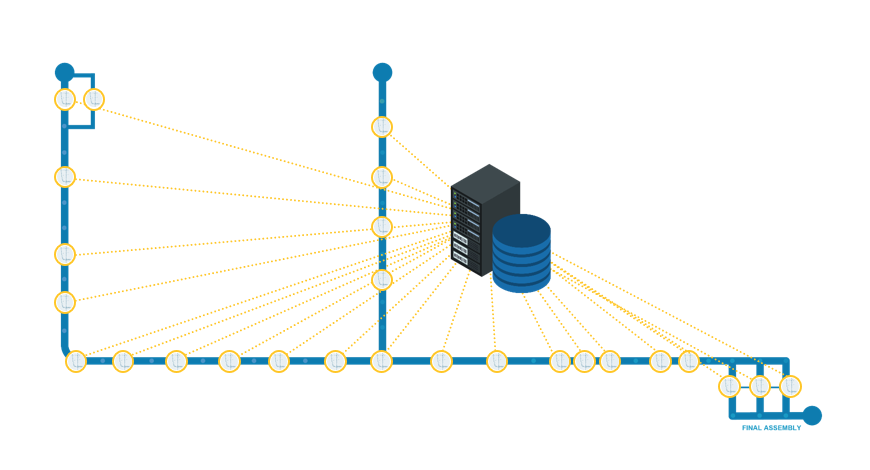

Scalar pass/fail data from end-of-line engine hot test cells would end up in one silo, entered manually and indexed by time and date stamp. Further up the line, some process stations, such as torqueing for bolts, would collect full process signatures indexed by serial number, but this data ended up trapped in a different silo.

Scalar pass/fail data from end-of-line engine hot test cells would end up in one silo, entered manually and indexed by time and date stamp. Further up the line, some process stations, such as torqueing for bolts, would collect full process signatures indexed by serial number, but this data ended up trapped in a different silo.

When a product came back from the field due to a customer complaint or warranty issue, it routinely took as long as a week to retrieve all the related data scattered across the plant.

The result? A lengthy feedback loop to trace the root cause and scope of a quality issue. In one case, a faulty gear system caused high-risk issues for customers in the field. Full production was halted until the cause of this defect could be found and addressed. That took several weeks – with substantial money and time wasted.

The power of an integrated enterprise manufacturing intelligence software

With access to data and analytics across all plants, root cause analysis is possible in minutes

This manufacturer had the data but lacked the means to integrate it all into a complete birth history record for each part, organized by serial number, that could easily be searched and analyzed for quick root cause analysis.

Sciemetric took all this disparate process and test data and converted it into formats that could be uploaded into a single database. The manufacturer’s quality teams were provided with the tools and knowledge to develop a suite of algorithms to quickly search, retrieve and correlate data from this single centralized repository.

Production and quality issues that once took this manufacturer days or weeks to identify and address can now be resolved in minutes.

Learn more about Sciemetric’s data analytics solutions for the manufacturing line.