Standard Test Pressure Ranges

Standard pressure transducer, valve manifolds, and regulator ranges:

-14.5, -2, -0.1 to 4” HG, 0.5, 2, 30, 100, 200, 400, 500, or electronic regulation (PSIG)

- Optional low volume test manifold available

- Optional high cV flow valves and manifold available up to 100 psig range allows 5X faster fill and exhaust to reduce cycle times on large parts

- Optional low volume (0.07cc) manifold available

- Absolute pressure transducer

- Six point pressure calibration

- Data resolution 0.00001 psi/ and scc/m.

- Optional electronic regulator available with multi-point calibration

Mass Flow Sensor Ranges

CTS will optimize the flow sensor and flow range of your Sentinel I28 leak testing equipment to meet the needs of your unique application. Contact our application engineering team for available mass flow sensors.

Selectable Test Units of Measure

Units of measure can be instrument global or per test program

Pressure

- PSIG

- PSIV

- inH2O

- cmH2O

- mmH2O

- kg/cm2

- ATM

- inHg

- cmHg

- mmHg

- kPa

- Pa

- MPa

- Bar

- mBar

- Torr

Flow

- sccm

- sccs

- scch

- slpm

- slps

- slph

- s

Time

- sec

- msec

- min

Tooling Control

- Expanded control through EtherNet/IP™ communication

- 12 inputs and 12 outputs, with up to five (5) programmable tooling motions with feedback

- Part marking control

- Tooling I/O is externally connected

- I/O 24 VDC: optional I/O cable “Cable,CTS, A12-610(standardx2)”

Test Data Storage

- Up to 5000 LIFO part results including date, time, barcode, and test results

- Selectable part serialization in the test data stream

- SPC data tracking for part traceability

- Expandable download through USB port

Electrical Requirements & Connectivity

- 88-264 VAC, 47-63 Hz, or optional 22-26 VDC

- RS232(2)

- Telnet(1)

- Email alerts

- Barcode ready (RS232)

- Mobile text

- USB mass storage device for backup, restore, and reports (FAT32, USB1.0,1.1,2.0)

- ¼” Colder fitting for test line attachment

Sentinel I28 Leak Testing Technologies

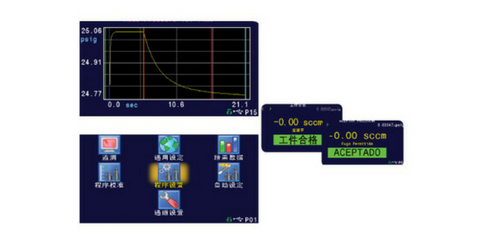

The Sentinel I28 leak detection system is configurable for a variety of pressure decay testing or mass flow testing requirements. It provides storage for up to 99 pre-programmed test sequences, and features a “Parent Program” that holds a customized test sequence for your multi-test application.

The test program can be selected via keypad, RS232, or binary. Test result evaluation is user-selectable (fail/pass/fail, etc.). The output format for test results can be configured to meet your needs.

Leak Test Options

- Pressure decay/vacuum decay: pressure change

- Pressure decay/vacuum decay: with certified mass flow leak standard

- Pressure decay/vacuum decay: pressure change/time

- Occlusion test (vacuum or pressure test)

- Mass flow: direct flow reading (pressure test only)

- Mass flow: continuous direct flow reading (pressure test only)

- Mass flow: with certified mass flow leak standard (pressure test only)

- Volumetric fill leak test: IPX6, IP67, sealed part leak test

Selectable Test Parameters

- Quick test

- Test pressure level compensation (selectable on/off)

- Adjustable environmental drift correction per test program

QualityWorX data management and analytics for the CTS Sentinel I28

CTS and Sciemetric have now made it possible to collect, store and analyze data from a selection of CTS instruments using QualityWorX.

Turnkey Package to Get Started

Customers can now connect several CTS Sentinel I28 instruments at a time using the QualityWorX CTS DataHub, a quick and easy turnkey platform for collecting and analyzing data, without requiring complex IT support or set up.

Scalable Database Options for Broader Data Collection

Want to collect data from more CTS instruments or to aggregate leak test information with data from other tests? Scale up to a QualityWorX database solution to cover as many stations as you need. Learn more about QualityWorX.

Current QualityWorX customers can now add CTS Sentinel I28 data to their database!

Contact your sales representative to talk about connecting Sentinel I28 instruments to your QualityWorX database.