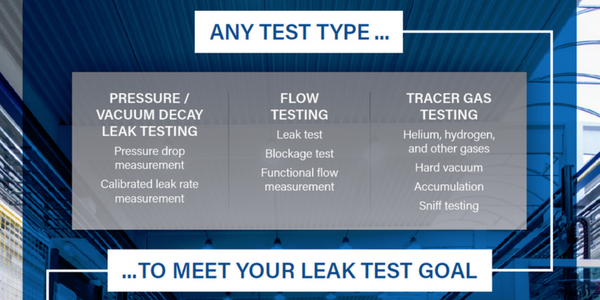

Many manufacturers say leak defects are the #1 issue affecting repairs, warranty, and productivity. Taking the best approach to leak test can be challenging, from selecting the appropriate test type (pressure decay? flow? one of the many other options?) and setting up the test station to managing test limits and cycle times for the right balance of quality and throughput.

Sciemetric, in collaboration with partners Cincinnati Test Systems and CTS-Schreiner, has extensive experience helping manufacturers spot leaks before they become problems. We also provide data intelligence solutions that let you keep those stations optimized and allow you to respond faster when the need of the hour arises in production.

Using manufacturing data to improve your leak test

Using the data generated during your leak test processes is the quickest way to improve your leak test. Sciemetric’s QualityWorX suite of data management and manufacturing analytics software allows you to consolidate your leak test process test with data collected from key application tests from across your line, enabling complete democratization of data: real-time analysis capabilities across your enterprise.

This data can be used for a variety of improvements on your leak test, including:

- Faster to find the right test limits

- Faster test setup

- Hit both Gage R and cycle time targets

- Immediately visualize the effect of changes on the test

- Ability to keep leak test optimized

- Birth history traceability

Download our e-book TO LEARN MORE:

Improving your manufacturing leak test with data

Top questions on leak test answered

Check out our Ask The Experts video series for short clips with answers to the top questions on leak test:

Articles, blogs and other resources that talk about popular leak test topics:

- Temperature Effects on Reported Leak Rate, an article in Quality Magazine

- How to conduct a leak test trial, from the Sciemetric blog

- What's the different between pressure decay leak and flow-based leak test?

- What you need to consider when choosing a leak test system

View more manufacturing leak test resources

The industry's largest portfolio of intelligent leak test systems

Get the right leak tester for the job

Sciemetric, Cincinnati Test Systems and CTS-Schreiner have combined products to offer one-stop shopping for manufacturers. With the breadth of our offering, you can trust that we will have the solution that will address your needs and specifications.

Leak testing is tricky: 7 steps to improve it today

Leak testing is a common test in manufacturing but it can also be a complex one as it involves so many variables. Typical challenges include:

- Station setup to provide the best test results

- Measuring or achieving repeatability (Gage R) targets

- Setting test limits to balance quality and cycle time

- Tracing the root cause of leak defects

Download our ebook to help find ways of addressing these issues and more so that you can improve your leak test.

Proven success in countless leak test applications

Sciemetric and our partners, Cincinnati Test Systems and CTS-Schriener, have been helping manufacturers perfect their leak test for decades. We have combined experience and expertise on a wide range of components and assemblies, including automotive and off-highway engine assemblies, fuel rail injector, carburetor, radiator, wheel hub, brake line, master cylinder, and more.

By implementing our leak test monitoring and data collection and analysis solutions, we have helped manufacturers across the globe identify defects that previously went undetected, enabled quick and effective root cause analysis, and provided complete traceability across each production line in the enterprise.

Leak Test Services

Leak testing can be complicated. Sciemetric provides a full range of support services to make sure you are confident and comfortable with your leak test. We offer leak test set-up, optimization, calibration, maintenance, data consultation, general training, and more.