How to improve valve tappet set monitoring: A case study

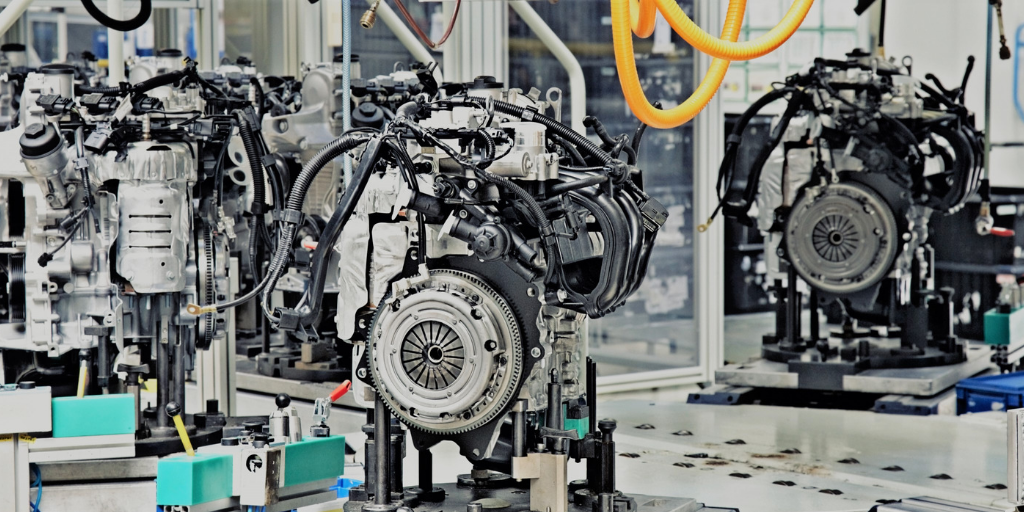

The valve tappet setting application can have a huge impact on the overall quality of an engine. If the valve tappets are not adjusted and tightened within precise parameters during manufacturing, it can cause premature wear and excessive engine noise during operation. Learn how Sciemetric helped an automotive manufacturer boost quality and repeatability with an efficient solution for the valve tappet set station.

Improve manufacturing defect detection using digital process signatures

Set more effective control limits on production tests using digital process signatures

Optimizing limits on your manufacturing test processes eliminates false failures and reduces the risk of giving bad parts a passing grade. This blog post discusses how to use digital process signatures to set more effective limits, more quickly, to produce higher quality parts, lower scrap/rework rates, and experience fewer recalls or warranty claims.

Adapt and adjust, quickly, to improve production using digital process signatures

Set up your line for success in 2021: Lessons for improving product line efficiency and effectiveness

Due to the circumstances of 2020, manufacturing budgets and timelines have been under an ever-increasing microscope. This sentiment certainly rings true when we looked back at the most-read content from our blog over 2020, where improving efficiency and effectiveness seem to be top-of-mind. Set your line up for success in 2021 with these tips from our most-read posts of 2020, here!

7 production data gaps that are slowing down manufacturing engineers

5 considerations when automating your quality control process on the manufacturing line

5 tips to improve production line efficiency in 2022

Enabling non-destructive testing in medical device manufacturing with in-process testing

How to improve defect detection on your assembly line, starting with these 7 common tasks

Regardless of where your plant lies on the digital transformation scale, your most essential tool for achieving practical and profitable change is your production data. Below, we look at 7 common tasks required on nearly any assembly line and how you can use your production data to do them better and more efficiently, achieving new levels of product quality and profitability.