Contributed by: Sciemetric Staff

With 2017 coming to an end, we are taking a look back at our most popular posts from the Sciemetric blog throughout this past year. The below posts are sure to offer tips and tangible insight to help make 2018 your best production year yet.

1) Getting your leak test right starts with data: Check out our e-book

Leak testing is often an art as much as it is a science.

Manufacturing quality engineers and machine operators must contend with many external factors that can undermine accuracy and repeatability.

This blog post highlights key insights from the Sciemetric e-book “7 steps to a better manufacturing leak test”, including tangible ways you can lever your production data to improve your process.

To read this blog, click here.

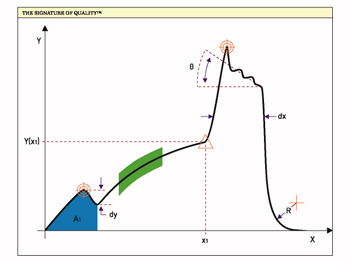

2) 5 ways a digital process signature can save time and money in manufacturing

This blog post describes the use of digital process signature analysis and its benefits for improving efficiency and ROI in manufacturing – including improving limit setting, optimizing test cycle times, quickly (and reliably) identifying the root cause of defects, and more.

How can you help your team save time, cut costs and boost quality? Find out in this blog post!

To read this blog, click here.

3) The Repair Bay, Part 1: What is defect data management and why should I use it?

The repair bay is often where parts from the production line that have been identified with problems are diagnosed and repaired by technicians. On the modern manufacturing line, repair bay operations must be viewed as much more than a reactive function, with technicians waiting to address individual problems as they arise.

This blog post provides insights on using data collection and analytics tools to drive your defect data management strategy for continuous quality improvement.

To read this blog, click here.

4) The Repair Bay, Part 3: A day in the life

This blog post takes a look at the different ways in which individuals from the plant floor to the office engage with and benefit from a repair bay data analytics system.

This includes an in-depth look at the day to day benefits from the perspective of the repair technician, the quality engineer, and more.

To read this blog, click here.

5) Using data to contain the damage of a recall

Sciemetric’s Richard Brine, CTO and Dave Mannila, Product Manager provide their tips for containing the damage and repercussions of a recall – using data. Tips include how to break down your data silos and how to use centralized data collection and analysis to quickly triage your production line and contain a warranty claim.

To read this blog, click here.