Choosing the right camera for your vision inspection

Are your machine vision needs on the production line better served with a smart camera, or a “dumb,” more basic one? Before you make the investment, consider these factors that can dictate which option is better for a given situation.

How to effectively store and manage machine vision images and data

The information generated by machine vision systems puts a whole new spin on the term “big data.” The raw image files output from vision systems are huge, and manufacturers can generate terabytes of image data in a month—even in a week! So, what do you do with all this data? Read more to find out!

Why relying on end-of-line is bad for your bottom line

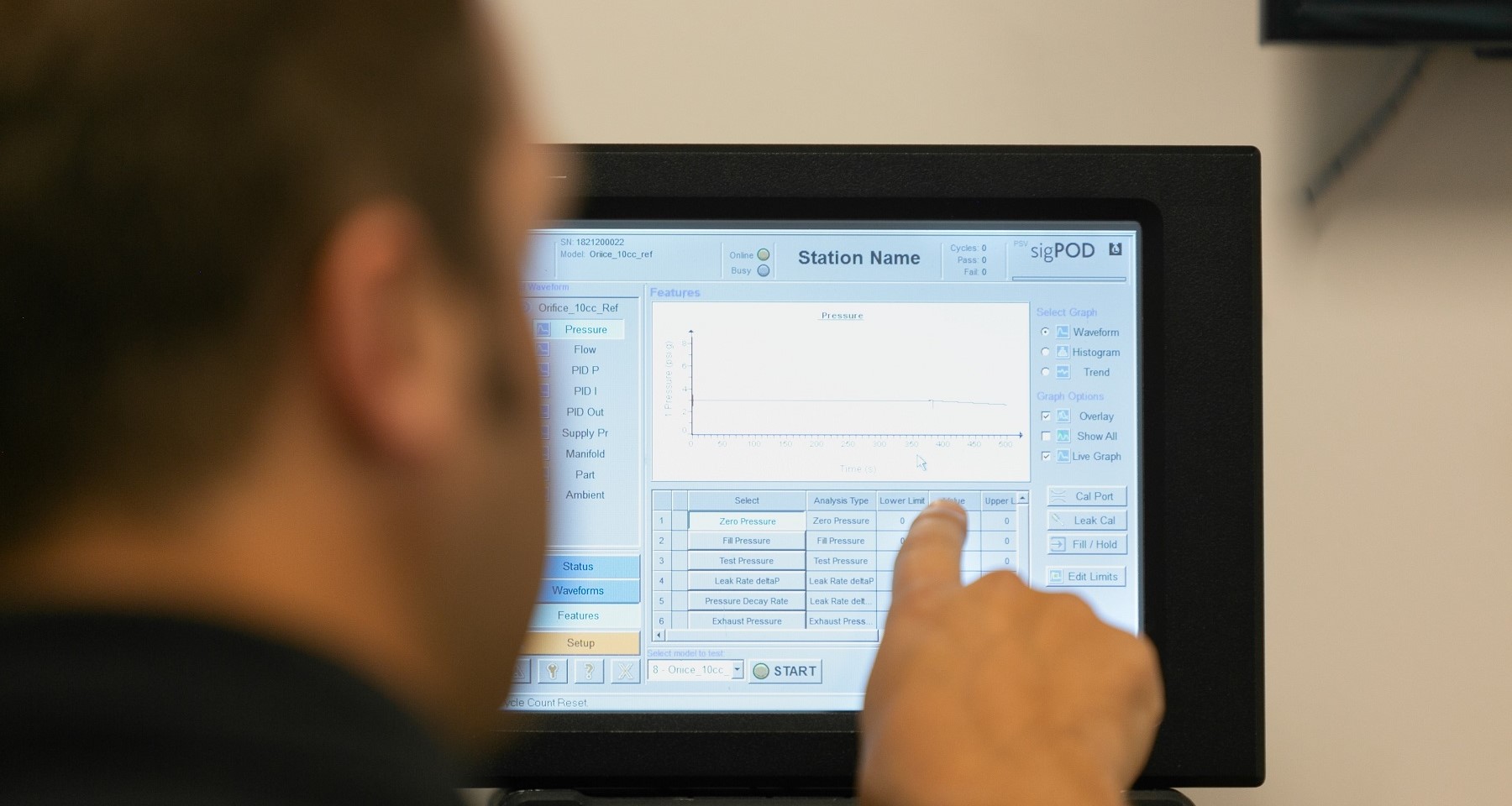

Digital process signature analysis: The first step to Industry 4.0

Many manufacturers continue to focus on data collection rather than data utilization. They don't yet have the modern data analytics tools in place that will allow them to squeeze from their part data the actionable insight that is crucial to meeting Industry 4.0 benchmarks they are seeking for quality, yield and traceability. Learn why digital process signatures are your first step to meet Industry 4.0 objectives.

A more reliable weld test through data, without the need for destruction

The traditional approach to testing weld integrity is often destructive pull-test, with its shortcomings. Perfectly good assemblies may be ruined, while faulty ones can still slip through and be shipped for use. With digital process signature analysis, however, all the metrics that identify problems can measured to catch defective parts.

How the network edge can help your plant or industrial operation optimize cloud resources

Many manufacturing and industrial facilities have chosen to recruit capacity from a public cloud service provider to help them manage their data. However, while the cloud is a relatively cost effective, simple to manage, and scalable solution to suit your needs, it can also create some other challenges. Learn more.

Optimize manufacturing test cycle times using digital process signatures

Integrators Part I: Reduce your risk, be on time and budget

Machine builders are always struggling to stay on budget, on schedule and on spec with their manufacturer customers. Joe Ventimiglio discusses how incorporating the data-driven quality management of Industry 4.0 into their builds can save them a lot of grief.