Contributed by: John Perkins - Senior Technical Support Specialist (Retired)

John Perkins is a manufacturing applications expert who has built hundreds of applications to help improve production and part quality. Though John is now retired, we can still answer any questions you may have at inquiries@sciemetric.com.

Noise, vibration and harshness (NVH) testing on the factory floor poses its share of challenges. With all that industrial background noise, it can be almost impossible to pick up specific sounds such as clicks, whirrs or buzzes. Placing a microphone close to the part doesn’t help.

Quality engineers may think their only option is to use an anechoic chamber, or traditional sound room, but in a production situation, this adds significant cost and complexity to the test process station.

An alternative method is to swap the microphone for an ICP-based accelerometer that’s connected to a test monitoring system, thereby capturing the full process waveform, or digital process signature, of the test.

Advantages of using an accelerometer for NVH testing

The advantage of an accelerometer is that it picks up the vibration that is creating the unwanted noise, instead of trying to record the sound itself. With proper mechanical isolation fixturing, the accelerometer is more immune to extraneous noise from the factory floor.

Place the accelerometer either directly on the part to be tested, or better yet, on the isolated tooling or test jig where it is in good mechanical contact with the part. You’ll be able to pick up even the slightest vibrations or noises.

This provides a simple but accurate method for isolating and identifying unwanted vibrations or noises, without the subjectivity and inconsistency of the human ear. And it can be deployed right on the factory floor.

We’ve deployed numerous test set ups like this with our signature monitoring system, sigPOD, using our PSV-based NVH template to collect noise traces as process signatures. This can be coupled with our advanced QualityWorx suite of data management and manufacturing analytics software.

A great feature of this setup is the ability to actually listen to the accelerometer data from a .WAV file, which can be reviewed right on the sigPOD using USB headphones. An accelerometer measurement “sounds” very much like the audible noise you actually hear during a test. This will allow you to identify the noises you are trying to eliminate and correlate them to specific features in the accelerometer signatures.

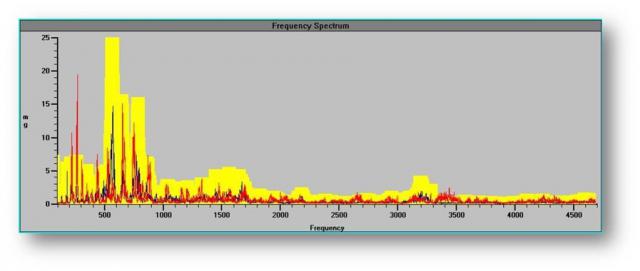

The signature shown above is for an automotive seat track assembly. Power was applied in the “UP” position and 30 khz data collected for eight seconds on the ICP accelerometer (note: a 10-Khz anti-alias filter is built into the ICP amplifier input plug). Time and frequency domain analysis was performed and a go-no-go decision made, with the test repeated for the “DOWN” motion. Listen to the sound files for an example of a “good” sample (corresponds with the black line) and a “bad” sample (red line on the signature).

Sound Samples

Click here to find out more information how we can help with your machine noise/sound and vibration testing needs. Contact us at inquiries@sciemetric.com to speak with John Perkins.