Machine data versus part data: pros and cons | Manufacturing Data Series, Part 3

When we talk to manufacturers, sometimes we find that the difference between machine data and actual part production data has gone unnoticed. While both have their role to play, one is not a substitute for the other, as they don’t measure the same things. This blog post discusses the pros and cons of these different data systems to help you decide what's right for you.

Considerations when digitizing paper-based records, automating defect detection and quality control on the production line

4 ways to make better use of data from stations on the production line

Data is everywhere on today’s production lines. The challenge is that though manufacturers may be collecting large volumes of data, it often isn’t being used proactively or efficiently to solve day-to-day problems. Consider the following best practices to start making better use of your production line data.

Smart cameras: Unlocking the ROI trapped in the black box

A smart camera or machine vision system can do so much more than basic, "dumb" cameras—but many manufacturers don't take advantage of their full capability in terms of data analysis. That’s where the opportunity arises to generate a strong return on your machine vision investment, unlocking the full potential of the "black box".

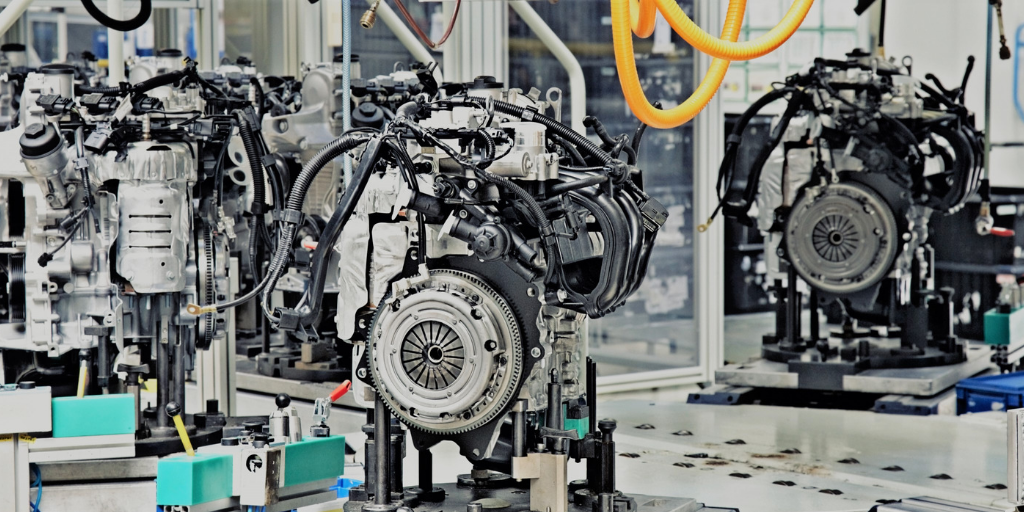

How to improve valve tappet set monitoring: A case study

The valve tappet setting application can have a huge impact on the overall quality of an engine. If the valve tappets are not adjusted and tightened within precise parameters during manufacturing, it can cause premature wear and excessive engine noise during operation. Learn how Sciemetric helped an automotive manufacturer boost quality and repeatability with an efficient solution for the valve tappet set station.

Improve manufacturing defect detection using digital process signatures

Set more effective control limits on production tests using digital process signatures

Optimizing limits on your manufacturing test processes eliminates false failures and reduces the risk of giving bad parts a passing grade. This blog post discusses how to use digital process signatures to set more effective limits, more quickly, to produce higher quality parts, lower scrap/rework rates, and experience fewer recalls or warranty claims.

Adapt and adjust, quickly, to improve production using digital process signatures

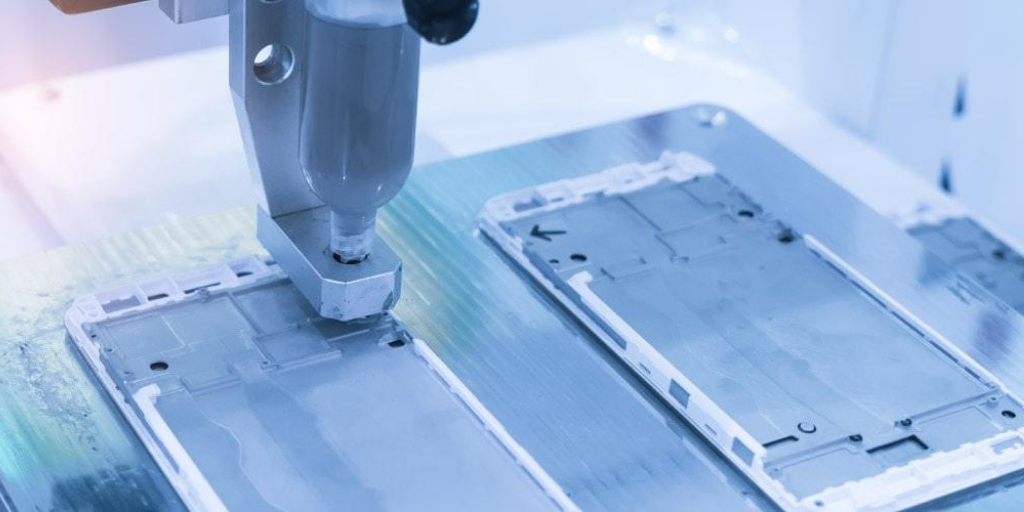

10 considerations for effective defect detection during dispense operations

Set up your line for success in 2021: Lessons for improving product line efficiency and effectiveness

Due to the circumstances of 2020, manufacturing budgets and timelines have been under an ever-increasing microscope. This sentiment certainly rings true when we looked back at the most-read content from our blog over 2020, where improving efficiency and effectiveness seem to be top-of-mind. Set your line up for success in 2021 with these tips from our most-read posts of 2020, here!