The Blackbelt is a precision benchtop leak test instrument designed for maximum performance and minimal space requirements.

- Sentinel Blackbelt brochure

- Sentinel Blackbelt Specifications sheet

- Sentinel Blackbelt Dimensions guide

The Blackbelt is a precision benchtop leak test instrument designed for maximum performance and minimal space requirements.

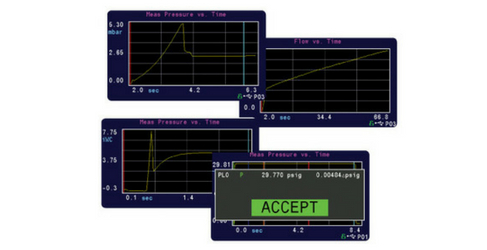

Advanced Features

Standard Features

Standard Test Pressure Ranges

Standard pressure transducer, valve manifolds, and regulator ranges:

-14.5, -2, 0.5, 2, 10, 30, 100, 200, 400, 500 or electronic regulation (PSIG)

Mass Flow Sensor Ranges

CTS will optimize the flow sensor & flow range per application. Contact Application Engineering for available mass flow sensors.

Pressure Selections

PSIG, PSIV, inH2O, cmH2O, mmH2O, kg/cm2, ATM, inHg, cmHg, mmHg, kPa, Pa, MPa, Bar, mBar, Torr

Flow Selections

Sccm, sccs, scch, slpm, slps, slph, scfm, scfs, scfh

Time Selections

Sec, msec, min

Units of measure can be instrument global or per test program

Tooling Control

Test Data Storage

Electrical Requirements and Connectivity

Testing Technologies