Data Management & Analytics

How to detect delamination of brake pads using impact response testing

Brake pads can be constructed of a variety of materials, which need to be securely bonded to a backing plate to function properly. Failure to ensure a proper bond between these materials can result in costly scrap and rework. In this blog post, Sciemetric's Jason Koval discusses how to detect delamination of brake pads using impact response testing.

Go beyond station checks to improve product quality and line efficiency: The value of process monitoring and data analytics

Machine data versus part data: pros and cons | Manufacturing Data Series, Part 3

When we talk to manufacturers, sometimes we find that the difference between machine data and actual part production data has gone unnoticed. While both have their role to play, one is not a substitute for the other, as they don’t measure the same things. This blog post discusses the pros and cons of these different data systems to help you decide what's right for you.

How long should I store my manufacturing production data? | Manufacturing Data Series, Part 2

What manufacturing data should I be collecting to improve part quality? | Manufacturing Data Series, Part 1

10 considerations for effective defect detection during dispense operations

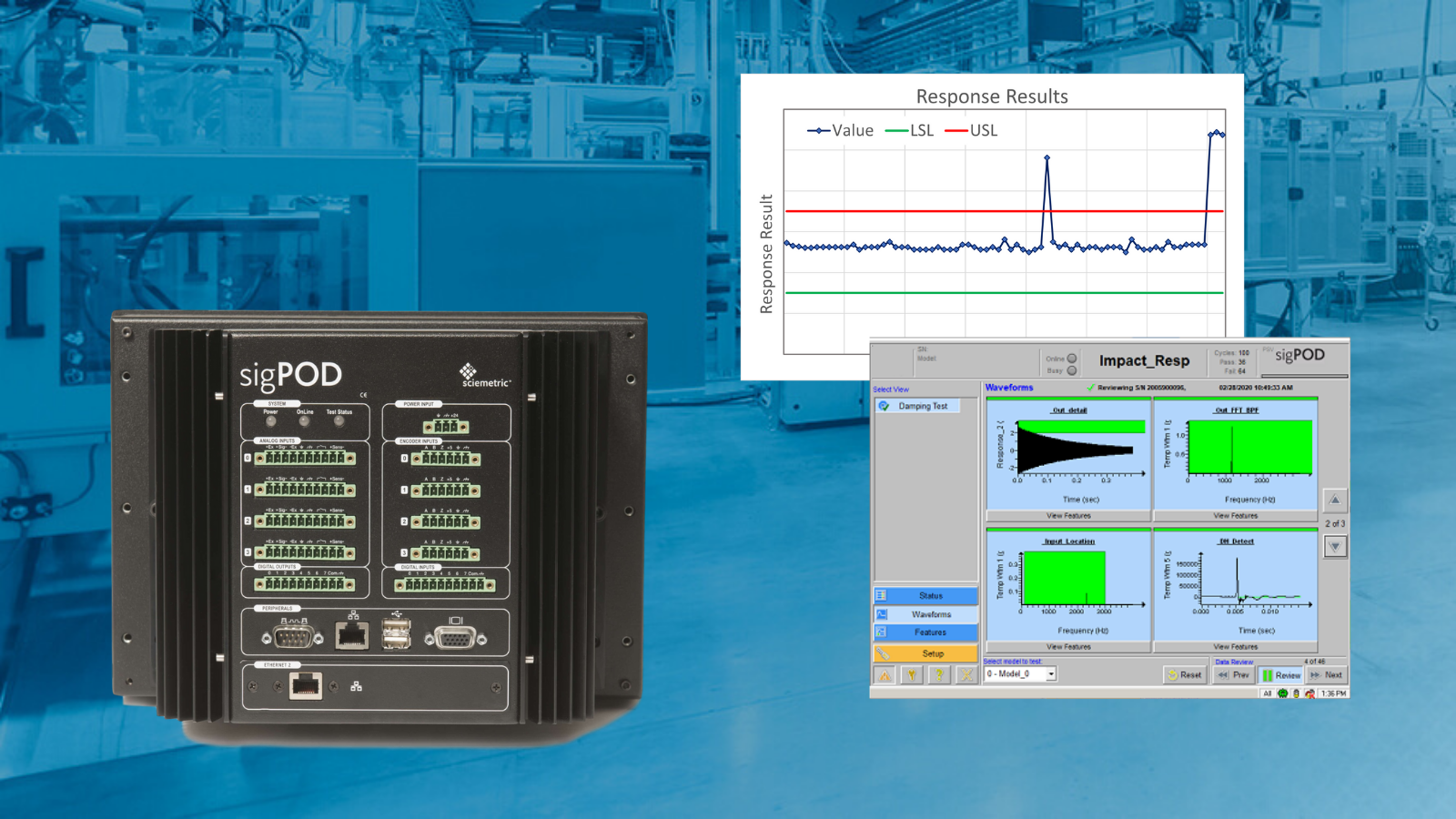

Continuously monitor and improve production using digital process signatures

Adapt and adjust, quickly, to improve production using digital process signatures

Optimize manufacturing test cycle times using digital process signatures

Set more effective control limits on production tests using digital process signatures

Optimizing limits on your manufacturing test processes eliminates false failures and reduces the risk of giving bad parts a passing grade. This blog post discusses how to use digital process signatures to set more effective limits, more quickly, to produce higher quality parts, lower scrap/rework rates, and experience fewer recalls or warranty claims.