Digital process signature analysis: The first step to Industry 4.0

Many manufacturers continue to focus on data collection rather than data utilization. They don't yet have the modern data analytics tools in place that will allow them to squeeze from their part data the actionable insight that is crucial to meeting Industry 4.0 benchmarks they are seeking for quality, yield and traceability. Learn why digital process signatures are your first step to meet Industry 4.0 objectives.

landing

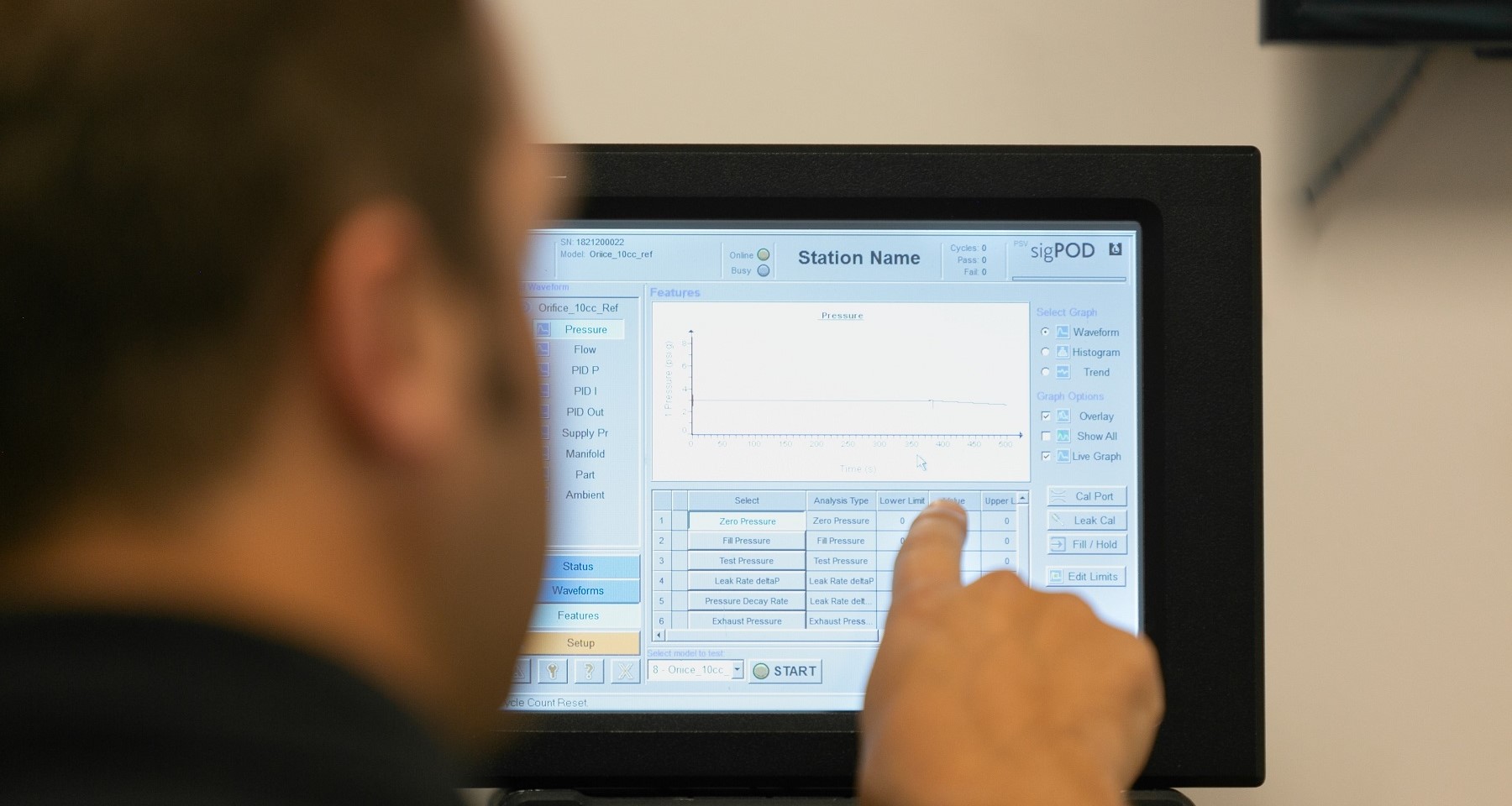

Process Monitoring, DAQ & Software for Industry 4.0

Enhancing process monitoring with process signature verification from Sciemetric is the key to boost quality, efficiency and first-time yield to achieve Industry 4.0 benchmarks.

Tags:page

Industry 4.0 — Digitization in the Smart Factory

Sciemetric has the products and experience to help industrial customers introduce Industry 4.0 concepts into their processes. Harness the Big Data generated in your connected production environment, then analyze it for faster, more reliable decision-making.

Tags:Sciemetric’s Studio 2.0 aiming to help manufacturers adopt Industry 4.0 trends

In this article for Canadian Manufacturing, Sciemetric's Product Manager, David Mannila, discusses the latest manufacturing trends, and how Sciemetric Studio 2.0 can be applied on production lines even with little to no automation or technology, helping even SME’s begin to adopt Industry 4.0 strategies.

product

Consolidate Manufacturing Data for Quick, Industry 4.0 Insight

From the production floor to the enterprise, Sciemetric data experts bring decades of experience and innovative approaches to capturing, storing and analyzing part data for faster issue resolution and increased yield, quality, and productivity.

Tags:Fastening, Pressing and Industry 4.0

Engineers can do more with force and torque data than simply make “good” or “not good” decisions about assemblies. Sciemetric's CTO, Richard Brine, is featured in this article in Assembly Magazine discussing the applications of fastening and press for Industry 4.0.

page

工业 4.0:智慧工厂的数字化

Sciemetric 所拥有的产品和经验,可帮助工业客户将工业 4.0 的概念引入他们的流程当中。利用连接生产环境中生成的大数据,加以分析,以获得更快、更值得信赖的决策。

Tags:solutions

Increase Manufacturing Production Output

Sciemetric’s data management and analytics capabilities deliver the tools and insight your team needs to overcome the quality and performance issues that hinder production line output.

Tags:resources

QualityWorX Brochure: Data Management and Manufacturing Analytics

Industry 4.0 is not just about collecting data. It’s about collecting the right data and being able to do more with it – something that makes a difference to quality, productivity and customer satisfaction. Sciemetric’s Data Management and Manufacturing Analytics solution includes all the key elements necessary for data-driven decision-making.

Tags:news

QualityWorX CTS DataHub claims the New Product of the Year Award at The ASSEMBLY Show 2018

The manufacturing industry, as represented at The ASSEMBLY Show, has chosen the QualityWorX CTS DataHub as the 2018 New Product of the Year.

Tags: