Contributed by: John Perkins - Senior Technical Support Specialist (Retired)

John Perkins is a manufacturing applications expert who has built hundreds of applications to help improve production and part quality. Though John is now retired, we can still answer any questions you may have at inquiries@sciemetric.com.

Question:

Dear John,

How do I catch a noisy actuator on the factory floor with all that background noise? Do I need to move the part to a “quiet room”?

Answer:

Well now, that’s a very good question. The problem with trying to pick up specific sounds, such as clicks, whirrs, or buzzes, is that they are very difficult to hear above all the background noise that is usually present on the factory floor. Even if you place a microphone as close as possible to the part under test, you’re still going to have the same problem. Fortunately, the solution is simple and does not require you to build an anechoic chamber!

The key is to use an accelerometer to pick up the vibration that is creating the unwanted noise, instead of trying to record the sound itself. By placing the accelerometer either directly on the part, or better yet, on the tooling or test jig where it is in good mechanical contact with the part, you’ll be able to pick up even the slightest vibrations or noises. Just connect the accelerometer up to a sigPOD and use our NVH (Noise, Vibration and Harshness) template in PSV to start collecting noise traces.

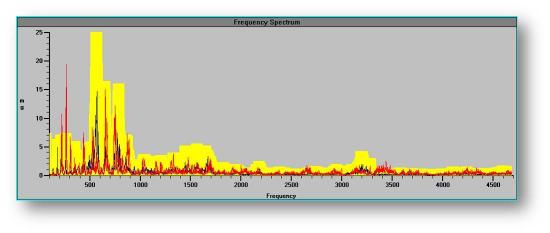

One of the really nice features of this application is the option to review the accelerometer data as a .WAV file, which you can then listen to right off the POD! You will be amazed at how much this accelerometer measurement “sounds” like the noise you are trying to capture. This will allow you to identify the noises you are trying to eliminate and correlate them to specific features in the accelerometer waveforms. Typically, I would use either a straight time-domain trace or take advantage of the FFT function in cases where you might see it better in the frequency domain.

What you end up with is a simple but accurate method for isolating and identifying unwanted vibrations or noises, without the subjectivity and inconsistency of the human ear. And it can be deployed right on the plant floor, no matter how noisy it is – no anechoic chamber required!

Power was applied in the “UP” position and data collected for 8 seconds at 10 kHz on the accelerometer. Time and frequency analysis was performed and a go-no-go decision made, with the test repeated for the “DOWN” motion. Listen to the sound files for an example of a “good” sample (corresponds with the black line) and the “bad” sample (red line on the signature).