Reliably and repeatably find process issues as they happen during part assembly to reduce costs and wasted cycles. Sciemetric’s in-process test and monitoring systems use digital signature technology to measure and analyze the entire waveform of a process for a more accurate pass/fail decision. Flexible for use across the production line, our solutions offer additional features to optimize limit setting, view and analyze data and more.

Sciemetric EDGE

Sciemetric EDGE is a universal industrial analytics platform that can help you perfect your processes in record time. This distributed data analytics system removes barriers to collecting and using data, for productivity improvements and cost savings.

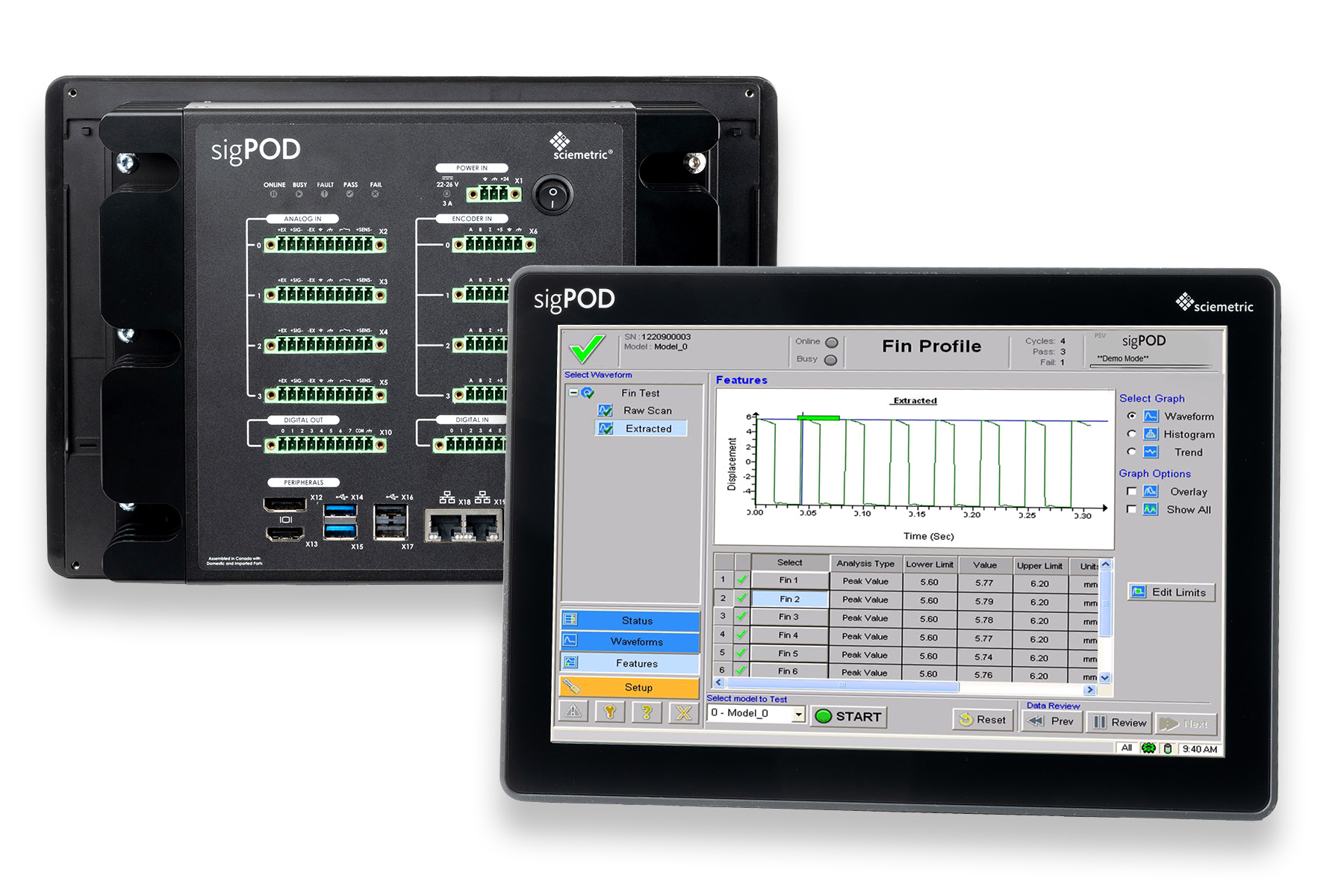

sigPOD

sigPOD delivers the real-time pass-fail feedback and the advanced defect detection capabilities to catch quality issues fast using advanced signature analysis and process signature verification.

FLEXIBLE SOLUTIONS FOR VIRTUALLY ANY PROCESS

Improve virtually any industrial process with Sciemetric EDGE

Sciemetric EDGE is a universal industrial analytics platform to help you perfect almost any process in record time. This modular, distributed data analytics system removes barriers to collecting data, driving productivity improvements and cost savings. Whether your goals are improved product quality, greater process reliability, increased efficiency, or enhanced test repeatability, Sciemetric EDGE can help you achieve them.

Boost the intelligence of your entire line with sigPOD process monitoring equipment

sigPOD is one of Sciemetric’s out-of-the-box solutions for monitoring test and assembly processes that standardizes part test and process monitoring onto a single platform for manufacturers. Our in-station process monitoring tool uses advanced signature analysis to deliver real-time pass/fail feedback along with advanced defect detection. It has a compact, robust design and is expandable to accommodate up to an additional 16 analog channels or 64 encoder channels.

With sigPOD, process signature verification can be deployed across the production line on virtually any manufacturing process. Gain the data-driven insight you need to compete in an Industry 4.0 world.

Improving manufacturing process monitoring with digital process signature verification

PSV technology exclusive to Sciemetric

A digital process signature is a visual representation of everything that happened through every millisecond of a manufacturing process or test cycle. It is visualized as a waveform through process signature verification (PSV).

By analyzing and collecting more data points than is typical of other quality assurance systems, PSV provides the most accurate, reliable, and repeatable measurement of manufacturing processes.

This provides a baseline profile that makes it easy to determine pass/fail in production real-time and establish a range of acceptable deviation. Defects can be caught quickly, before the part moves on to the next station.

Real-time production monitoring systems find defects at their source

Many discrete manufacturers continue to rely on process monitoring systems that don’t collect and analyze the data to catch defects as they occur. If defects are flagged further down the line, it can take days or weeks to trace and address root cause. Faulty units can end up in the field, resulting in unsatisfied customers and costly recalls.

Sciemetric’s intelligent process monitoring systems empower your team to take a more effective approach to ensuring quality. Our real-time production monitoring systems are compatible with standard production line tests including:

- Crimp: Detects missing wires and terminals, crimp issues, incorrect wire gauge and other defects.

- Dispense: Provides accurate detection and visualization of bubbles, air voids, or partial hardening during the dispensing and application of sealants, coatings, and adhesives.

- Force-Distance Monitoring: Monitors every step of the press force operation to accurately and reliably catch incorrect orientation, improper insertion, cracks, and other defects as they occur.

- Torque: Multi-channel torque and encoder signal support for testing engine shafts, electric motors, and more.

- Noise and Vibration: Production line testing for rotating machinery and motorized assemblies.

- Gauge and Profile: Identify surface defects, detect incorrect assemblies, and monitor planarity in flat parts.

- Weld: Monitors voltage, current, force, distance, amplitude, frequency, and power in automotive assemblies, medical assemblies, and more.

- Leak Tests: Plug and play connectivity for leak testing engine chambers, medical devices, and other parts and components where seal integrity is critical.

By providing real-time manufacturing process monitoring and analysis, our systems identify and reject defective parts on the line before they can advance to the next step. Best of all, our systems are universal and agnostic. Equipping your line with this capability doesn’t require a costly rip and replace. Having a single-source process monitoring system also makes it easier to train personnel and collect and manage data.

Talk to us about your process test or monitoring application today

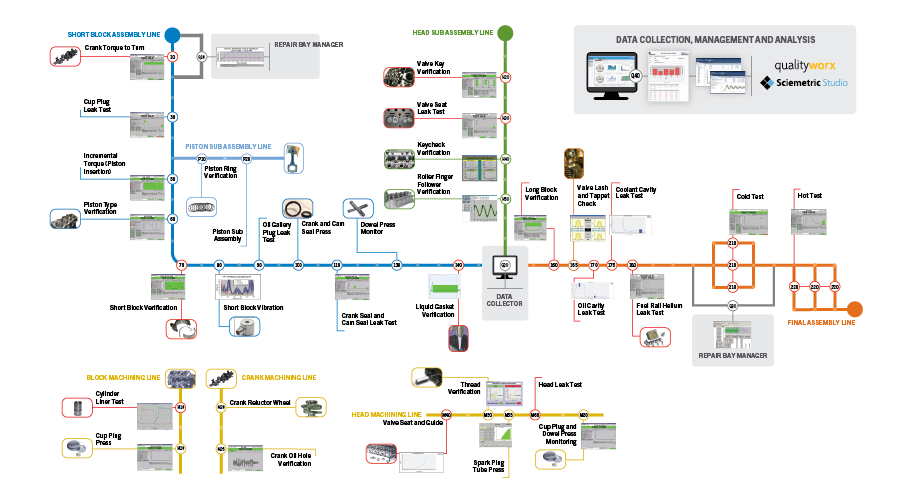

Manufacturing analytics bring the production line to your desktop

Developments in the area of Industry 4.0, including automation and data exchange, have reshaped manufacturing and helped companies increase production while improving product quality and reducing overhead costs. Without an effective in-process monitoring system, however, manufacturers can't take full advantage of the actionable insights offered by this expanded data and analytics capacity.

Learn more about Sciemetric’s manufacturing analytics platforms to visualize and analyze sigPOD data for continuous improvement across your organization:

- Harness the power of your production data at a strategic level with QualityWorX

- Optimize production with the simple manufacturing analytics of Sciemetric Studio

Sciemetric's real-time industrial manufacturing process monitoring software solutions give you the insight you need to improve processes and ensure product quality. Our process monitoring tools utilize cutting-edge data management and analytics technology and integrate easily into your manufacturing stations. The systems are delivered in a complete package containing process monitoring software, hardware, and an interface for easy set-up--no coding required.

Contact us to learn more about our industry-leading process monitoring tools for discrete manufacturing.