5 ways a digital process signature can save time and money in manufacturing

We give a primer on how comprehensive data collection from across the plant floor, coupled with digital process signature analysis, can achieve the sometimes contradictory goals of reduced production costs and improved quality.

What manufacturing data should I be collecting to improve part quality? | Manufacturing Data Series, Part 1

Machine data versus part data: pros and cons | Manufacturing Data Series, Part 3

When we talk to manufacturers, sometimes we find that the difference between machine data and actual part production data has gone unnoticed. While both have their role to play, one is not a substitute for the other, as they don’t measure the same things. This blog post discusses the pros and cons of these different data systems to help you decide what's right for you.

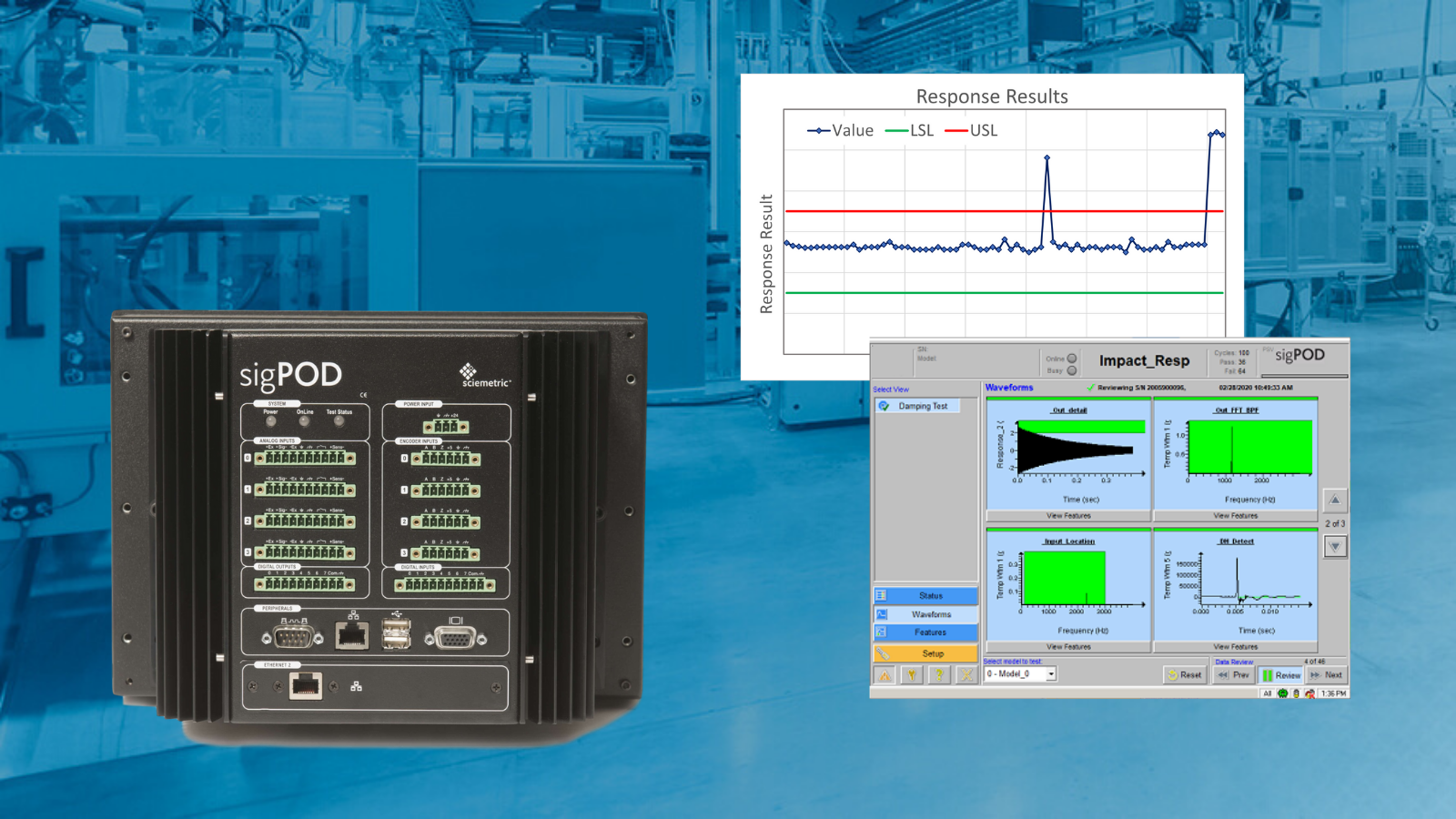

How to detect delamination of brake pads using impact response testing

Brake pads can be constructed of a variety of materials, which need to be securely bonded to a backing plate to function properly. Failure to ensure a proper bond between these materials can result in costly scrap and rework. In this blog post, Sciemetric's Jason Koval discusses how to detect delamination of brake pads using impact response testing.

Considerations when digitizing paper-based records, automating defect detection and quality control on the production line

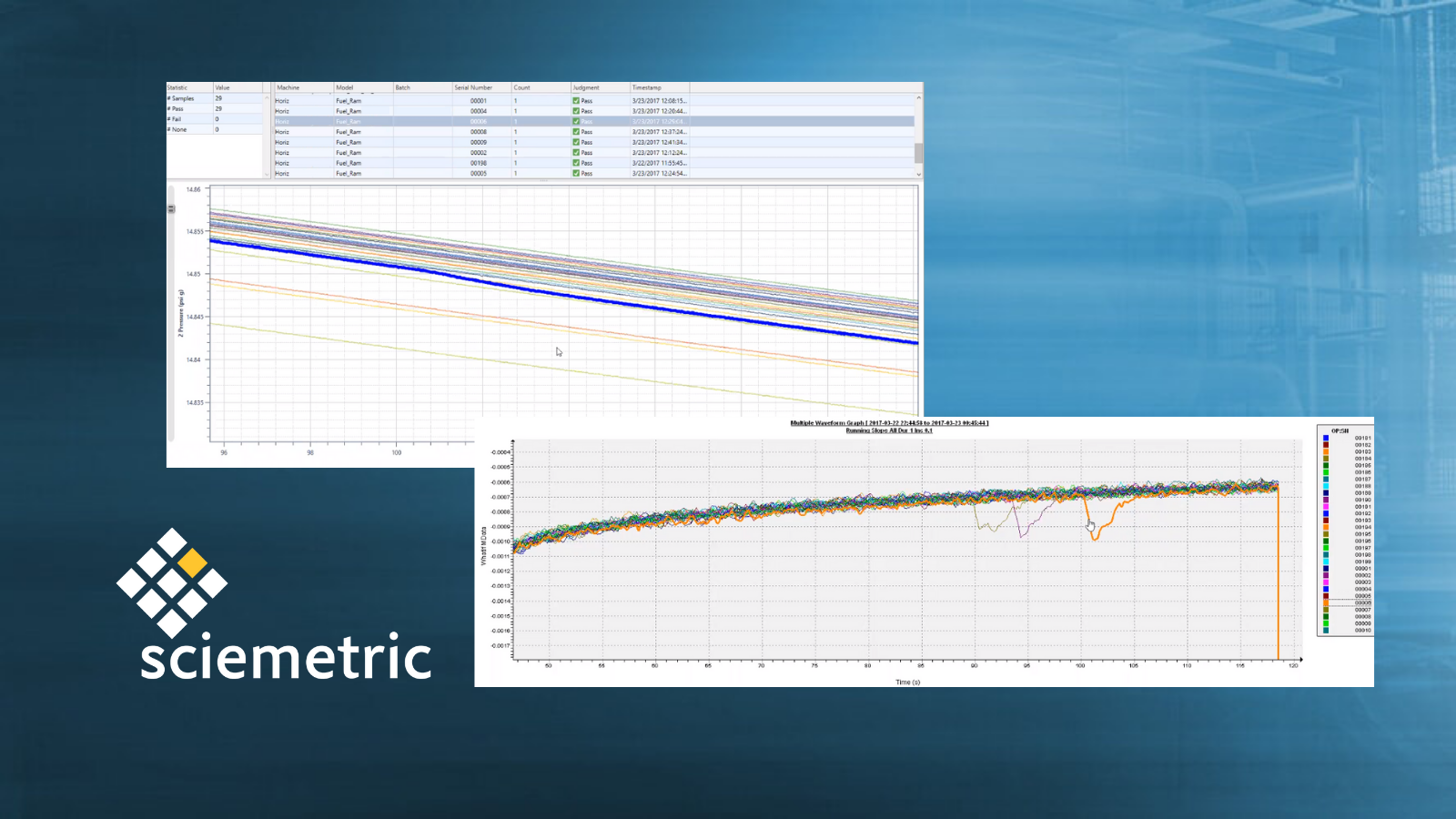

4 ways to make better use of data from stations on the production line

Data is everywhere on today’s production lines. The challenge is that though manufacturers may be collecting large volumes of data, it often isn’t being used proactively or efficiently to solve day-to-day problems. Consider the following best practices to start making better use of your production line data.

Sciemetric data analytics tools enabled engine manufacturer to link EOL failure to cracked check valves—see how!

What our survey of Smart Manufacturing Magazine’s readers told us

We teamed with Smart Manufacturing Magazine on a survey to better understand how readers use data collected from the production line versus how they would like to use it, to drive productivity, quality and profitability in their plants. Here is what the results tell us.

How to trace root cause after a warranty claim or product recall

When a product comes back with a warranty claim, the next step is to determine root cause. Robert Ouellette discusses how digital process signature analysis is the key to trace root cause, address the problem fast, contain the scope of a recall and ensure it never happens again.

Dear John: What can I do with my manufacturing production data?

Question: Dear John, Now that I’ve collected all this production and signature data, what can I do with it? Answer: That data is a goldmine, just waiting to be mined. Let’s start by looking at the pass/fail data, which can be translated into yields. Comparing …