Contributed by: Sciemetric Staff

Reduced production costs and improved quality isn’t an oxymoron… really.

It’s only to be expected that engineering and process staff might have a rocky relationship with the big promise of Industry 4.0. Achieving the goal of the connected factory where every piece of equipment digitally connects with another and every unit in production is traceable can seem daunting.

Which it is, if you still rely on the wrong tools to do the job.

Making your data work for you

Take any busy production line producing thousands of complex assemblies every day. If it can go wrong, it likely will. To ensure quality and the highest possible yield, staff can lose days ploughing through reams of spreadsheets to review and compare data from each station along the line.

Everyone understands the importance of data to Industry 4.0. The challenge is understanding what kind of data and what depth of data will arm the team on the factory floor with the insight they need to effect change and deal with the issues that can undermine quality and efficiency.

This is a big data challenge. Traditional methods of quality control that rely on collecting scalar data – only a handful of data points from each process or test cycle on the line – simply cannot deliver the detailed data sets that are needed.

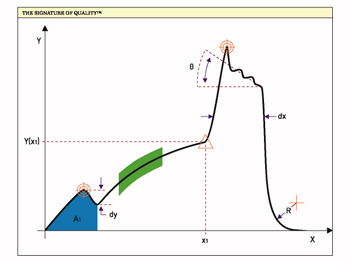

But if you capture the full waveform from each process or test cycle, and collect this data into a single database to crunch the numbers and visualize the results, time is now on your team’s side. They no longer have to sift through piles of spreadsheets. This is digital process signature analysis.

Benefits of digital process signature analysis

How does it help your team save time, cut costs and boost quality? By making your in-process testing smarter.

Take the guesswork out of limit setting

Use production statistics, including all waveform data, to calculate optimal test limits. With an archive of stored data, you can run a range of tests and simulations without having to run additional parts through a process to validate parameters.

Optimize test cycle times

Review that historic data and run those simulations to also see where and how a test cycle can be shortened without impacting quality assurance. This boosts productivity and can reduce the number of test stations.

Identify the root cause of defects

By capturing all the waveform data, tagged to the individual serial number, it’s much easier and faster to trace a problem to its source and mitigate the impact. Quarantine only the specific parts or assemblies that are suspect instead of risking an entire production run.

Launch machines or lines more quickly

This same insight can be used to troubleshoot and dial in new equipment and new lines faster. We worked with one client that launched new lines around the world an average of four times faster, for estimated average savings of US$4 million per plant.

Predict your maintenance requirements

Small changes in a process’s typical waveform signature can be an early warning sign that equipment is wearing or drifting out of alignment.

Whether it’s called “Industry 4.0” or “IIoT” the nature of manufacturing has changed. But proven tools do exist to help your team keep up and gain the upper hand. Learn more about Sciemetric data intelligence tools for the smart factory.