The crimp process involves compressing two pieces of metal or some other malleable material together through a process of deformation such as bending. Achieving a quality crimp is critical, as even the smallest of defects can impact the reliability of wire connections.

Typical issues identified using a crimp force quality monitor

and crimping defect analysis

- Missing wires or terminals

- Missing or soft crimps

- Missing strands or ears

- Debris caught in the terminal

- Double crimps

- Incorrect wire gage

- Improper placement

These and other crimp operations issues are often not detected until much later in the assembly process. With any defect, the longer it takes to catch, the more costly it is to address. Sciemetric provides accurate, effective, real-time crimp force monitoring to detect all these defects and more.

Contact us about CRIMP MONITORING

Benefit from a crimp force monitoring system—monitor crimp in real time

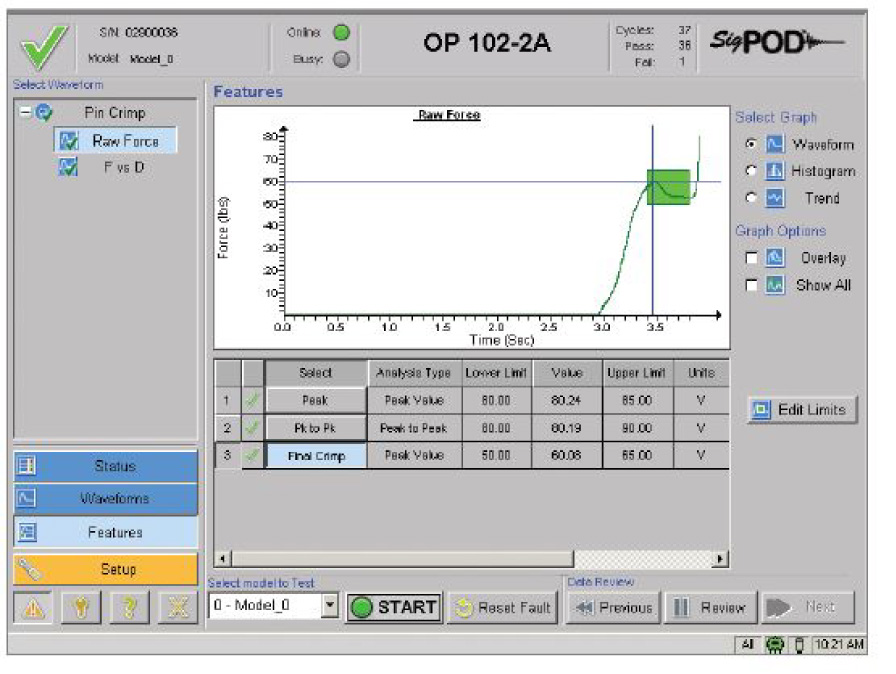

Our real-time crimp monitoring systems provide a reliable, data-driven and objective means to determine the quality of your crimp operation. Sciemetric’s sigPOD teamed with our digital process signature analysis software allow you to monitor and gain access to pass-fail feedback on your crimp operations in real time.

sigPOD monitors force versus distance and force versus time waveforms during the entire crimping process. This approach provides a consistent measurement standard for evaluating the quality of the crimping operation, offering unmatched defect detection.

A non-destructive crimp test; more reliable and efficient than destructive pull tests

A common alternative to crimp process monitoring are destructive pull tests. However, this approach to testing is time-consuming and costly. It can end up destroying the part and is not very accurate as you are left to determine failure rates based on the test sample. Using this method, it is impossible to identify all individual parts with defects. As a result, you may end up accidentally shipping defective parts, or issuing a product-wide recall when it is not necessary.

Crimp force monitoring is a non-destructive alternative that resolves these issues by providing real-time pass/fail feedback and analysis on each specific part or component.

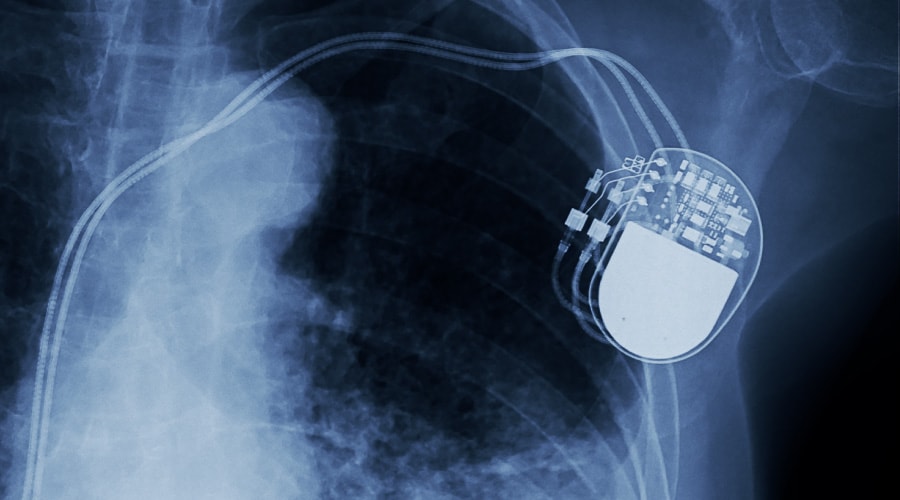

Application example: Monitoring crimp in medical device manufacturing

A manufacturer of medical devices needed a reliable means to monitor and verify the crimping operation for wire leads connected to the body of a pacemaker. As a medical device subject to strict regulatory oversight, the manufacturer is under tremendous pressure to ensure zero defects.

Sciemetric deployed a sigPOD system that provided the required reliability to identify defective crimps. The crimp force monitoring solution eliminated the destructive testing previously used – pull testing of the leads on a batch of pacemakers – and replaced it with a data-derived, objective decision that was more consistent with the requirements for the industry.

Monitor crimp in nearly any manufacturing application

We specialize in designing and manufacturing accurate defect detection solutions for crimp monitoring and other processes. Our solutions are flexible and can be applied to nearly any crimp operation on your line. See a few examples below to learn more how our systems have been used to monitor and improve your crimp applications for some other manufacturers:

Crimping copper terminals onto wires for automotive wire harnesses

Crimping for spool valves with a solution that took less than a day to develop

Rivet quality by analyzing crimp force

Enable crimp quality traceability with Manufacturing Analytics

By collecting the results from crimping operations by part and integrating them with data from other processes on the assembly line, manufacturers can act more quickly to resolve quality and productivity issues. Explore how our QualityWorX suite of data management and manufacturing analytics software can consolidate crimp monitors data with all your other production part data to provide a practical and faster way to:

- Identify the root cause of defects or issues affecting throughput

- Very quickly pinpoint affected parts to avoid a mass recall or stop ship

- Continuously optimize stations by using the data to set limits, cycle times, etc.

- Demonstrate conformance for each part

see how QualityWorX provides better visibility into part data